Stampo per componenti di tubazioni di approvvigionamento idrico

Mold for Water Supply Piping Components Molds for water supply piping components are critical tools in the manufacturing of plumbing systems, ensuring the production of high-quality, durable, and leak-proof parts. These molds are designed to create components such as fittings, valves, connectors, and joints, which are essential for efficient water distribution in residential, commercial, and industrial applications. Material and Design Considerations The molds are typically made from high-grade steel or aluminum to withstand high pressure and temperature during the injection molding process. The choice of material depends on factors like production volume, component complexity, and cost efficiency. Steel molds offer superior durability for large-scale production, while aluminum molds are lighter and more cost-effective for prototyping or smaller batches. Precision is paramount in mold design to ensure dimensional accuracy and smooth surface finishes. Advanced CAD/CAM software is used to create detailed 3D models, optimizing the mold for manufacturability. Features like cooling channels, ejector pins, and venting systems are integrated to enhance cycle times and minimize defects such as warping or air traps. Manufacturing Process Injection molding is the most common method for producing plastic piping components. Thermoplastics like PVC, CPVC, PEX, and PP are melted and injected into the mold cavity under high pressure. The material cools and solidifies, taking the shape of the mold before being ejected. For metal components, die-casting or forging may be used, requiring molds with higher heat resistance. Quality and Performance The mold must produce parts that meet stringent industry standards for pressure resistance, corrosion resistance, and longevity. Tight tolerances ensure proper sealing and compatibility with other piping systems. Post-molding processes, such as deburring or surface treatment, may be applied to enhance functionality. Innovation and Sustainability Modern molds incorporate innovations like multi-cavity designs to increase production efficiency and reduce material waste. Sustainable practices, such as using recycled plastics or energy-efficient molding machines, are also gaining traction. In summary, molds for water supply piping components play a vital role in delivering reliable, efficient, and safe plumbing solutions. Their design, material selection, and manufacturing precision directly impact the performance and longevity of the final products.

Prodotto

Classificazione:

-

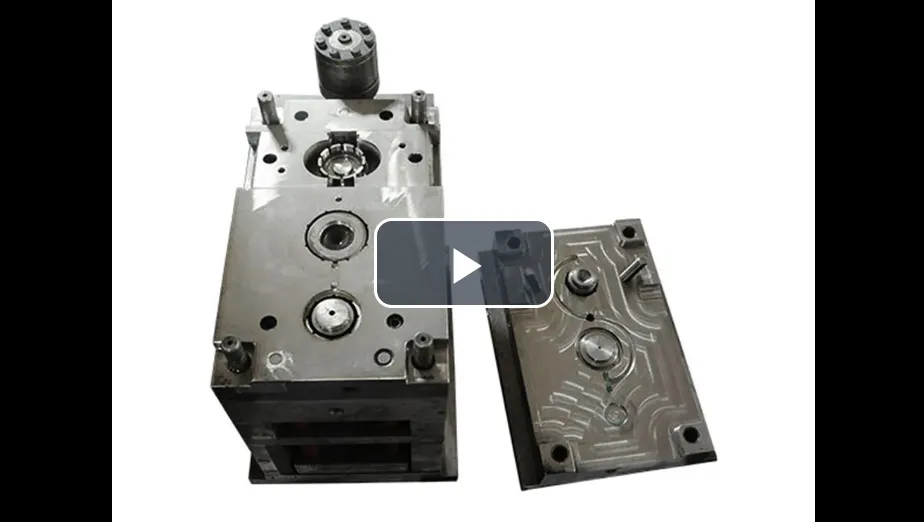

Stampo per raccordo per tubo con maniglia per valvola in PVC

La loro classificazione: Stampo raccordi per valvole a sferaVisualizzazioni: 578Numero:Tempo di rilascio: 2025-09-17 00:24:22Stampo per raccordo per tubo con maniglia per valvola in PVCNome dello stampo:Stampo per raccordo per tubo con maniglia per valvola in PVCCavità: 8 cavitàDimensioni dello stampo: 50 mmAcciaio per stampi: 2738 o 718 per cavità e nucleoCancello: cancello direttostruttura dello stampo: palo superiore sporgenteDurezza del nucleo/cavità: HRC 38-42° dopo il trattamento termico sotto vuotoMacchina per lo stampaggio a iniezione: 180 T Taizhou Huangyan Hong Jin Mould Co., Ltd è stata fondata nel 2002. Siamo professionisti nella progettazione e produzione di stampi per raccordi per tubi da oltre 23 an...

Notizie

Classificazione:

-

[industry news]I seguenti fattori sono influenzati nella lavorazione degli...

2024-09-06 16:57:27

Caso

Classificazione:

Video

Classificazione:

Scarica

Classificazione:

Nessun risultato di ricerca!

Reclutamento

Classificazione:

Nessun risultato di ricerca!

Prodotti consigliati

Nessun risultato di ricerca!

Whatsapp

Whatsapp Telefono

Telefono