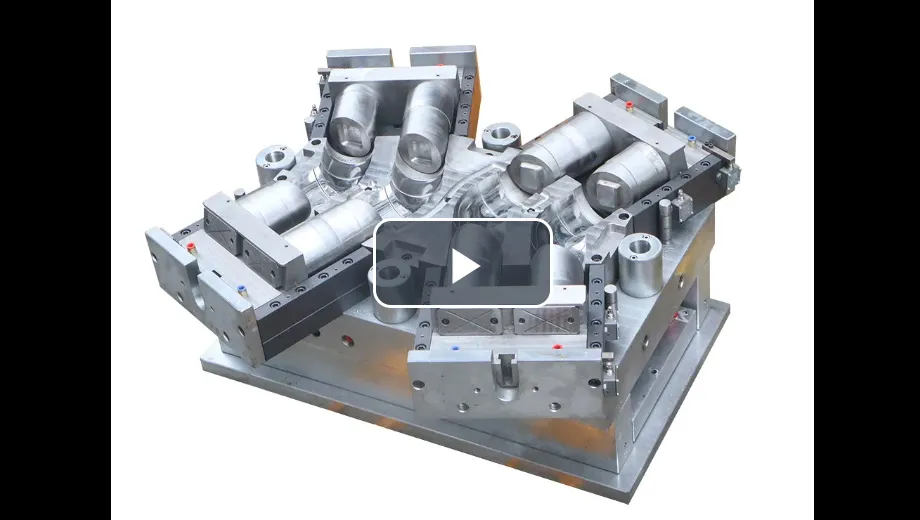

Stampo per raccordi per tubi con piega a P

P-Bend Pipe Fitting Mold: Design and Functionality A P-bend pipe fitting mold is a specialized tool used in the injection molding or blow molding process to manufacture P-shaped pipe fittings, which are essential components in plumbing, drainage, and industrial fluid systems. These fittings are designed to change the direction of fluid flow by 180 degrees, often used in traps to prevent backflow and block harmful gases. The mold must ensure precision, durability, and efficiency to produce high-quality fittings that meet industry standards. Key Features of the Mold 1. Material Selection The mold is typically made from high-grade steel, such as P20, H13, or stainless steel, to withstand high pressure, temperature, and wear during production. The choice of material ensures longevity and consistent performance over thousands of molding cycles. 2. Precision Engineering The mold is CNC-machined to exact specifications, ensuring tight tolerances for the P-bend’s curvature, wall thickness, and connection points. Advanced CAD/CAM software is used to design the mold cavity and core, optimizing flow paths for molten plastic or other materials. 3. Cooling System An efficient cooling system is integrated into the mold to reduce cycle times and prevent defects like warping or sink marks. Cooling channels are strategically placed to ensure uniform heat dissipation, maintaining dimensional stability in the final product. 4. Ejection Mechanism The mold includes ejector pins or plates to safely remove the molded P-bend without damaging its structure. The ejection system must be carefully designed to avoid deformation, especially given the fitting’s curved shape. 5. Surface Finish The mold cavity is polished or textured to achieve the desired surface quality on the P-bend. A smooth finish reduces friction for fluid flow, while textured surfaces may be used for grip or aesthetic purposes. Production Process The molding process involves injecting molten material (such as PVC, PP, or ABS) into the mold under high pressure. After cooling, the mold opens, and the fitting is ejected. Post-processing steps like trimming, deburring, or quality inspection may follow. Applications P-bend pipe fittings are widely used in residential and commercial plumbing, sewage systems, and industrial pipelines. The mold must produce fittings that are leak-proof, corrosion-resistant, and capable of handling varying pressures and temperatures. Conclusion A well-designed P-bend pipe fitting mold is critical for manufacturing reliable, high-performance fittings. Its precision engineering, durable construction, and efficient cooling and ejection systems ensure consistent production quality, meeting the demands of modern piping systems.

Prodotto

Classificazione:

-

Stampo per raccordo per tubo a gomito ridotto in PVC

La loro classificazione: Stampo per raccordi per tubi in PVCVisualizzazioni: 521Numero:Tempo di rilascio: 2025-11-13 20:36:05Stampo per raccordi per tubi a gomito riduttore in PVCNome dello stampo:Stampo per raccordi per tubi a gomito ridotto in PVCCavità: 6 cavitàDimensioni dello stampo:75x50 110x50 110x75Acciaio per stampi: Germany2316 china2316 or4cr13 per la cavità e il nucleoCancello: cancello direttostruttura dello stampo: cilindro dell'olioDurezza del nucleo/cavità: HRC 40-45° dopo il trattamento termico sotto vuotoMacchina per lo stampaggio a iniezione: 400 T Taizhou Huangyan Hong Jin Mould Co., Ltd è stata fondata nel 2002. Siamo professionisti nella progettazione e produzione di stampi per raccordi per t...

Notizie

Classificazione:

-

[industry news]Comprendere gli stampi per raccordi per tubi in PE: una guid...

2024-08-31 08:23:58

Caso

Classificazione:

Video

Classificazione:

Scarica

Classificazione:

Nessun risultato di ricerca!

Reclutamento

Classificazione:

Nessun risultato di ricerca!

Prodotti consigliati

Nessun risultato di ricerca!

Whatsapp

Whatsapp Telefono

Telefono